Milling wood is an essential step in transforming raw logs into usable lumber. It is a process that involves cutting, shaping, and refining the wood to create products that are used in various industries such as construction, furniture making, and woodworking. Let’s dive into the process of milling wood and explore the steps involved:

From Logs to Lumber: The Process of Milling Wood

1. Logging and transportation: The milling process begins with the logging of trees. Once the logs are felled, they need to be transported to the sawmill. This may involve loading them onto trucks or using specialized machinery for larger logs.

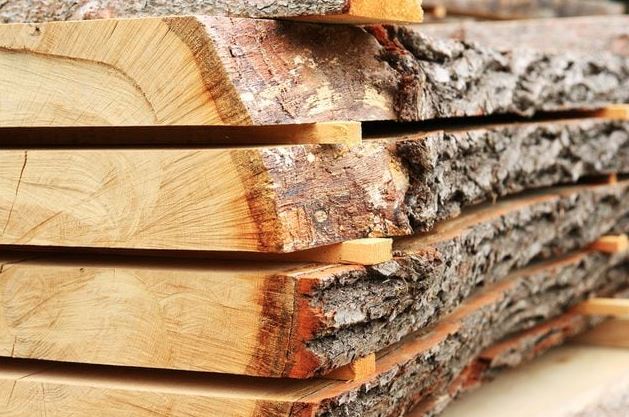

2. Debarking: Once the logs are at the sawmill, the first step is to remove the outer layer of bark. This is usually done using mechanical debarking equipment or sometimes even manually with tools like peeling spuds. Debarking helps prepare the logs for further processing by exposing the raw wood beneath the bark.

3. Sawing: The next step is sawing or cutting the logs into rough lumber. This can be done using different sawing techniques, including:

– Plain sawing: The most common method where the log is cut parallel to its center, producing boards with a varied grain appearance.

– Quarter sawing: The log is cut perpendicular to its growth rings, resulting in boards with straight grain patterns.

– Rift sawing: A variation of quarter sawing that produces boards with a narrower range of grain patterns.

– Live edge or slab sawing: Cutting the log into thick slabs while keeping one or both natural edges intact.

4. Drying: After sawing, the freshly cut lumber contains a significant amount of moisture. To make it usable, the wood needs to be dried. This can be done through air drying, where lumber is stacked and allowed to dry naturally, or through kiln drying, where controlled environmental conditions speed up the process. Proper drying helps prevent warping, shrinking, and cracking of the wood.

5. Surfacing: Once the lumber is dry, it needs to be surfaced to achieve smooth and uniform dimensions. This involves removing any imperfections, such as knots or rough spots, using planing machines or other milling equipment. Surfacing also ensures that the wood has consistent thickness and a smooth finish.

6. Sorting and grading: After surfacing, the lumber undergoes a sorting and grading process. It is inspected for quality, taking into account factors such as species, grain pattern, color, and any defects present. The wood is then sorted into different grades based on its intended use and quality standards.

7. Finishing: Depending on the specific requirements, some lumber may go through additional processes such as sanding, staining, or applying protective coatings. These finishing touches enhance the appearance, durability, and usability of the wood for its intended application.

The process of milling wood requires a combination of specialized machinery, skilled operators, and knowledge of wood characteristics. It is a crucial step in transforming raw logs into the various products we use in our daily lives. Whether it’s the frame of a house, the surface of a table, or the components of a piece of furniture, the milling process plays a vital role in preparing the wood for its end-use.